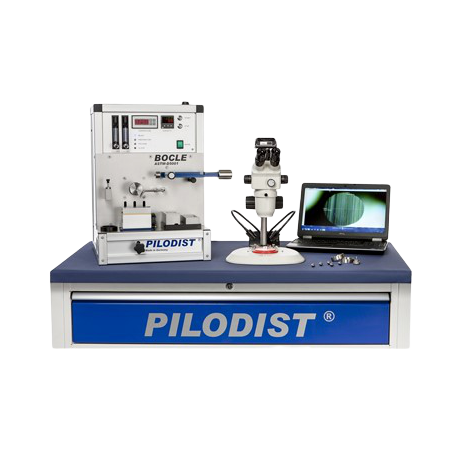

Ball on Cylinder Lubricity Evaluator

Test Equipment for Measurement of Lubricity of Aviation Turbine Fuels by the Ball-on-Cylinder Lubricity Evaluator according to ASTM D-5001.

Fully Automatic Test Equipment for Measurement of Lubricity of Aviation Turbine Fuels by the Ball-on-Cylinder Lubricity Evaluator according to ASTM D-5001.

The BOCLE-equipment according to ASTM D-5001 measures the actual wear scar size with a test ball specimen. The wear scar is generated by the friction between the stationary ball and a rotating cylinder. A part of the rotating cylinder is immersed in the turbine fuel tank (50 ml) and covered with the turbine fuel. The temperature of the fuel tank is controlled, as well as the relative humidity of the air which is circulated into and above the test fluid – the air flow rate is controlled, too. The Test Ball is loaded by a constant weight for the test period 30 min. After the test the minor & major axis of the resultant wear scar are measured with a microscope. The wear scar defines the lubricity of the aviation turbine fuel or other liquids.

Partner: PILODIST GmbH